GOLLER EFFECTA

GOLLER high performance washing compartment EFFECTA Modul Anti-Curl

GOLLER EFFECTA MODUL ANTI-CURL is a newly-designed washing compartment which maximizes the flexibility in applications and brings the washing experiences to a brand new level.

1. By minimizing the occurrence of curling edge and crease marks

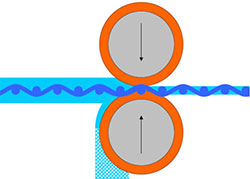

EFFECTA MODUL ANTI-CURL is designed particularly for Woven bottom weight and denim with high content of elastic weft processing. The ingenious way of putting the 2 rows of middle support rollers between the row of top rollers and the row of bottom rollers of EFFECTA MODUL ANTI-CURL which leaves the free fabric path in between in 360mm only and thus minimizing the occurrence of curling edge and crease marks. A higher washing efficiency can also be achieved since the extra 2 rows of middle support rollers provide more nips for fabrics during washing process.

2. By enhancing the compatibility of EFFECTA with different units.

EFFECTA MODUL ANTI-CURL is designed specifically for enhancing the compatibility of EFFECTA with different units. It applies the same design principle as the one of SINTENSA CYCLONE TANDEM by incorporating the modular-design intermediated trough with squeezer into the washing compartment - EFFECTA MODUL ANTI-CURL in this case. This modular design has further enhanced the compatibility of EFFECTA with the latest version of Sintensa washing compartment- SINTENSA CYCLONE TANDEM, Oxidator chemical application, swelling, shrinkage and washing compartment and Universa dwelling and washing compartment, etc. With the advancement of applications compatibility, EFFECTA MODUL ANTI-CURL can not only complete Goller’s product portfolio but also enable Goller to be excelled in every continuous open-width washing occasion.

There is no better match for the bulk of woven fabric than an up-and-down-washer. The EFFECTA is the classical machine for all the washing purposes. On top of that we have all the features needed for special requirements: Double loop, indirect heating, special fabric guiding for sensitive fabric and our famous power sprays, which are not only boosting the washing efficiency, but also your overall performance.

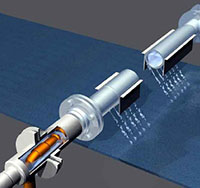

Meander counter flow

Intermediate squeezing for bath separation. Washing is worth nothing if the concentration of contamination is not reduced from bath to bath. Intermediate squeezers ensure that the highly polluted dyeliquor from the previous bath is not getting into the next (cleaner) washing compartment. If the squeezers are not big enough (20 -30 kN), a lot of contaminated water will get through. And if the sueezing unit is built into the washing compartment, they are exposed extremely to the heat, the steam and the chemicals of the process. As a result the rubber coating will suffer above average. To have them in a separate unit in between the washing boxes also makes the maintenance much easier.

Big windows for easy access to the inside of the machine: Your maintenance will like it and keep the machine in a good shape all the times.

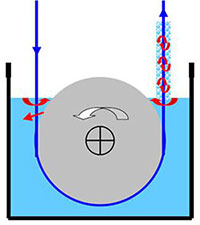

Washing mechanics with single loop: The wahing liquor is squeezed through the fabric by the force created in the nip between the roller surface and the fabric. The surface of the fabric additionally is flown against by the turbulence created by the movements of the roller inside the washing chamber. On top of it the surface is rinsed by the water which flows back during the ascent of the febric towards the top roller.

The efficiency of the overall washing process depends very much on the amount of water that will be provided to the top roller. This is the reason, why up-and-down washers normally require a certain speed to work efficiently.

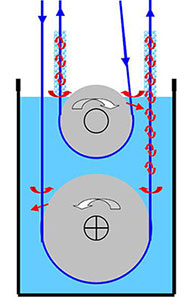

Washing mechanics with double loop. Advantages compared to the single loop: more washing mechanics, more fabric content per wash box. Disadvantage: Accessibility.

Power sprays to increase the washing effect. The spraying device applies the washing liquor onto the surface of the fabric evenly from side to side with a variable power to suit the design of the textile in the best way possible. The result: Higher washing effect- especially at the beginning of a washing process, where most of the contamination is on the surface of the fabric.

With additional steam, the THERMOFLUSH concept is able to heat the fabric up in a very short period of time. This additional temperature again helps cleaning particulary from the core of the fiber.