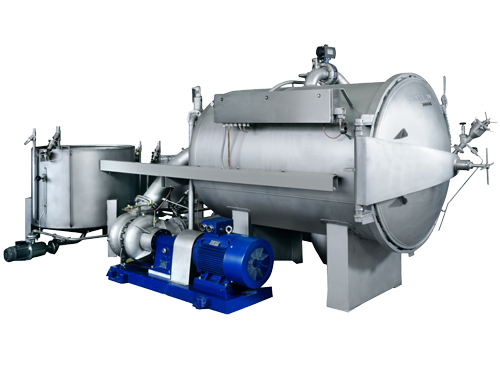

THEN HST (Beam Dyeing)

High-temperature piece dyeing machine

High-temperature THEN HST piece dyeing machine represents a highly versatile and economic system for the dyeing of large quantities of standard items.

Carefully considered and globally proven system design offers the ideal preconditions for the rational and perfect bleaching and dyeing of wide woven fabrics and knits.

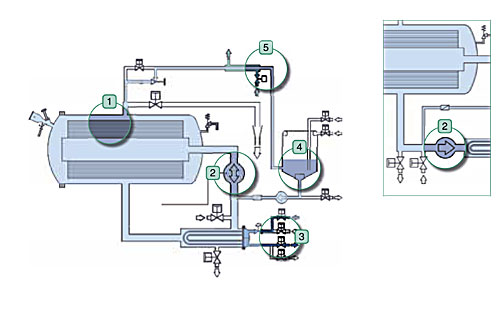

The liquor pressure and quantity are adjusted to the respective type and quantity of fabric. The special layout of the pressure pump circuit ensures constant and safe deaeration of the machine.

Various beam diameters are available, depending on the type of fabric involved. Several beams are arranged in line within the machine for the dyeing of fabrics with narrower widths.

Dye beam carriers

In the dyeing autoclave, the dye beam stands on a mobile carrier, which can accommodate differing beam diameters.

Dye beams

Dye beam diameters and perforations determine the quality of the goods. Various beam diameters are available in line with the type of fabric being...

Sampling

A specially developed sampling device facilitates sampling during ongoing operations.

Fabric type

Various beam diameters are available in line with the type of fabric being used.

In the case of the THEN HST, ecology and economy are far more than mere buzzwords. Indeed, a range supplementary devices is available in order to raise the systems efficiency still further:

Above please find technical data for some standard machines, other diameters / length are provided on request.

High-temperature THEN HST piece dyeing represents a highly versatile and economic system for the dyeing of large quantities of standard items. Globally proven design offers the optimum prerequisites for the efficient and perfect bleaching and dyeing of weaves and open knits.

The THEN HST can be supplied with either an axial reversible pump for knits and permeable weaves, or a centrifugal pump for dense woven fabrics.

The liquor pressure and volume are adjusted to match the respective fabric type and quantity. A second liquor circuit leads to the expansion and preparation tank via a pressure pump with pre-connected recooler and inspection glass. The pump generates static pressure, which can be infinitely adjusted and remains constant throughout treatment, irrespective of the temperature. Machine topping up can be completed at any time using the pressure pump.

Laboratory and sample beam dyeing machines

The sales programme contains laboratory and sample beam dyeing equipment of various sizes for dyeing experiments and sample batches. Small units are delivered in compact design as tabletop devices or in a base frame. In all units, sampling takes place via a sluice, which is used to take a sample directly from the batch. This ensures complete compatibility between the sample and the end product.

THEN-DYNET – the complete control unit

The intelligent THEN-DYNET control unit consists of a Windows® PC with touchscreen and a main control unit (MCU).

On the one hand, in network operation, the control system can access the control station data and, on the other, the complete control system can also be operated from the control station.

Batch processing is shown in real time. Apart from the set and actual values of the machine, defects and manual interventions by the operator are also registered.

Dyeing beams and other accessories for beam dyeing machines

suitable for your beam dyeing machines, we supply the necessary accessories in the right size and execution.

Dye beams with diametres from 50 up to 1000 mm, graduated in lengths from 1 m up to 4 m, the corresponding dye beam carriers to be introduced into the

autoclave, collars covering the outside or the inside, tension straps with and without radial sticks, couplings and transport trucks, etc. This list only reflects a part of our

product variety on this field. We have the proper solution also for your demand! Contact us!

| Model (ø/length) | A [mm] | B [mm] | C [mm] |

| HST 90/18 | 4150 | 1700 | 1650 |

| HST 90/35 | 6060 | 7300 | 1650 |

| HST 105/18 | 4950 | 1850 | 1750 |

| HST 105/35 | 6950 | 2000 | 1750 |

| Model (ø/length) | A [mm] | B [mm] | C [mm] |

| HST 130/18 | 5750 | 2250 | 2050 |

| HST 130/35 | 7400 | 2250 | 2050 |

| HST 155/18 | 6050 | 2650 | 2400 |

| HST 155/35 | 8450 | 2950 | 2400 |

Steel grades

Liquor carrying parts in special steel, material no. 1.4571 / 1.4404 (AISI 316 Ti / 316 L).

The right to make design changes is reserved, the quoted dimensions are non-binding.