THEN AIRFLOW® SYNERGY

AERODYNAMIC High Temperature Piece Dyeing Machine

SYNERGY 250kg/chamber

SYN G2 300kg/chamber

SYN 8 250 or 300kg/chamber

The new THEN-AIRFLOW® SYNERGY represents the combined result of the entire technological possibilities provided by the latest, patented THEN-AIRFLOW® technology. Through the interplay of all the technical possibilities and functions, economic and ecological advantages are achieved, which up to now, were unobtainable with the available dyeing technology.

Let the Air Flow

The patented aerodynamic system is based on the principle that the fabric transport is effected by air only, which means that as opposed to a hydraulic dyeing machine, no dye liquor or aqueous medium is required to transport the fabric. The fabric is constantly in motion from loading to the batch end, even during the discharge and filling processes.

No Limits

Knits and woven fabrics from light up to heavy weight and virtually any fibre or fibre blend can be bleached and dyed without machine modifications or changes. The modular system of the THEN-AIRFLOW® SYNERGY allows taylor made machine configurations, which guarantees maximum efficiency.

Proven Success

Several hundred plants in successful operation around the world document the reliability and economy of this dyeing system, which is based on aerodynamic principles.

Ongoing Research

Ongoing, further development guarantees reliable and long-term investment protection. Moreover, the diversity of the applications offered by the system is genuinely outstanding.

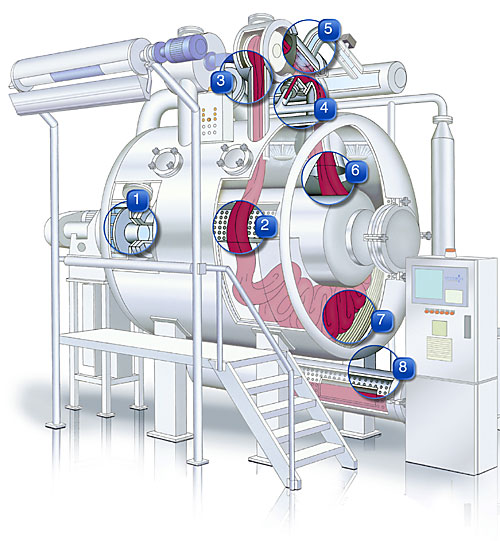

1. Aerodynamic fabric transport. Economical frequency controlled blower. 2. Safe fabric transport. Optimized plaiting with less creasemarks due to aerodynamic transport. 3. Active fabric flow control, resulting in slippage regulation as well as detailled control of speed. The benefit: gentle fabric treatment. 4. Unique rinsing method. Short process times with highest rinsing efficiency. 5. Highest dyeing safety. Aerodynamic fabric transportation without hydrolic and dyeing in saturtated steam atmosphere. 6. Optimized plaiting for gentle and defined fabric handling. 7. Separated dyebath and fabric. PTFE-gliding bars for optimized treatment of the fabric surface. 8. Dyebath collector. Self cleaning filter keeping the dye liquor clean and reduces the stand times between the batch.

1. Aerodynamic fabric transport. Economical frequency controlled blower. 2. Safe fabric transport. Optimized plaiting with less creasemarks due to aerodynamic transport. 3. Active fabric flow control, resulting in slippage regulation as well as detailled control of speed. The benefit: gentle fabric treatment. 4. Unique rinsing method. Short process times with highest rinsing efficiency. 5. Highest dyeing safety. Aerodynamic fabric transportation without hydrolic and dyeing in saturtated steam atmosphere. 6. Optimized plaiting for gentle and defined fabric handling. 7. Separated dyebath and fabric. PTFE-gliding bars for optimized treatment of the fabric surface. 8. Dyebath collector. Self cleaning filter keeping the dye liquor clean and reduces the stand times between the batch. Aerodynamic High Temperature Piece Dyeing Machine

The ecological solution

For hundreds of years, water, which is a precious human resource, has been the most important element in textile finishing. Water has been used in large quantities for fabric dyeing.

A step in the opposite direction was taking place in 1979. The THEN Research and Development department asked itself the question how the enormous volumes of water required for piece dyeing could be reduced along with the related energy costs.

This rethink commenced with the development of the THEN-AIRFLOW® technology, which already faced the fact that even though water had served as a transport medium in the past; it was and is still today not available everywhere in sufficient quantities.

However, water is today an even more expensive medium. The answer to this is the new THEN-AIRFLOW® SYNERGY. This model offers previously unattainable economic and ecological advantages.

The outstanding advantages are:

Unlimited flexibility with regard to all fibres (except pure wool) and fabrics weight classes between 50-800 g/m.

The lowest liquor ratio on the market: man-made fibres approx. 1:2, natural fibres 1:3 to 1:4, depending on the article and structure.

Energy savings of approx. 40% compared to hydraulic jet-dyeing machines.

A reduction in the overall process time of around 25%.

The most advanced piece-dyeing machine available today. Providing a competitive edge through the lowest available processing costs.

Lowest water consumption and effluent represent an ecologically sound solution.

The modular system for maximum efficiency

The new THEN-AIRFLOW® SYNERGY is the perfect dyeing machine for almost every application, fabrics made of natural or man-made fibres and its blends. The different modules allow the perfect set-up for any customer requirement.

Through the interplay of all the technical possibilities and functions, each model represents the optimum solution for an economical and ecological dyeing process. The achieved economy is quite considerable.

Salt feeding device, suitable for pourable common salt or Glauber's salt

Recommended for all CO and CO/PES dyeings with reactive dyestuffs. Suitable for pourable common salt or Glauber's salt. The minimum dosing time is 20 minutes with full salt vessel (valve fully opened). If process-related a longer dosing time is required, it can be programmed via the control.

Example of use:

AIRFLOW AFS 900, light reactive dyeing, 40 g salt per liter total quantity of salt: 144 kg minimum dosing time: 7.2 min. (= 20 kg / min.)

Process:

Models and technical specifications

| AIRFLOW® SYNERGY | 50 | 250 | 500 | 750 | 1000 | 1500 |

| Dimension A [mm] | 4000 | 4300 | 4300 | 4300 | 4300 | 4300 |

| Dimension B [mm] | 3370 | 3580 | 3580 | 3580 | 3580 | 3580 |

| Dimension C [mm] | 4320 | 4800 | 6400 | 8100 | 9650 | 12500 |

| Dimension D [mm] | 4000 | 4550 | 4620 | 4750 | 4900 | 5250 |

| Dimension E [mm] | 4000 | 5150 | 5500 | 5650 | 6150 | 6350 |

| Dimension F [mm] | 5500 | 5700 | 6000 | 6200 | 6500 | 7300 |

Operating temperature: max. 140 °C at 3 bar overpressure.

Liquor carrying parts in special steel, material no.1.4571(AISI 316 Ti).

THEN Maschinen GmbH reserves its right to make design changes, the quoted dimensions are non-binding.