GOLLER SINTENSA

GOLLER high efficiency washing compartment

SINTENSA CYCLONE TANDEM

The newly-designed GOLLER washing compartment - SINTENSA CYCLONE TANDEM can reduce fabric’s running tension by means of the following two points.

The new generation of GOLLER high efficiency washing compartment - SINTENSA CYCLONE TANDEM is an innovation to the typical washing compartment in large size and in large volume, which can indeed guarantee energy-saving, emission reduction and production costs-saving and make the open-width washing process for knitted fabric more smooth and efficient.

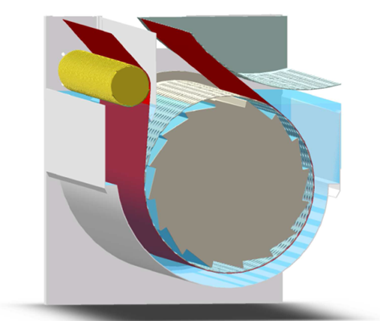

An inside rotor generates a constant penetration of the washing liquor through the fabric. During this process the fabric lies flat on the surface of the outside drum and is not exposed to any tension.

On top of that the differences between the different guiding rollers and drums are so little, that the fabric edges are not having many opportunities to curl.

The SINTENSA principle not only hosts the superior washing mechanics of the inside drum. The intelligent sequence design with processes with penetration followed by those which cover mainly the surface the SINTENSA principle ensures, that the contamination is not only worked out of the fabric- it also is carried away immediately afterwards to prevent the cloth from re-soiling.

SINTENSA principle with inside rotor and outside drum. The inside rotor speed is different from the outside drum- consequently the washing liquor collected in between the rotor drum and the perforated drum will be squeezed through the fabric with every turn of the rotor. Inside out and outside in.

Washing mechanics inside the SINTENSA compartment. Independent of the speed and with hardly any fabric tension applied the washing takes place. Inverter controlled for a flexible treatment of different qualities. No other system available provides this feature.

To serve the requirements of the fabric in terms of tension (or rather non-tension) nearly every roller which is involved in the fabric guiding is driven individually. By controlling the different drives by the PLC we can accommodate even the most delicate qualities with the SINTENSA. Safe and reproducible.

https://youtu.be/pECvB8q_0z8